GET-TO-KNOW PLM

PLM is a diverse company with employees who come from very unique backgrounds. Hardip Pannu, Danil Botoshansky, and Daniel Silva all bring valuable knowledge and insight to the table because of their individual experiences. Let's get to know them personally a little bit better with these three fun facts:

HARDIP:

Favorite thing to do in downtime?

I like to read and learn things on any and all subjects which include anything from computer

programming, electronic circuits, to engineering. I read a lot online and it doesn't have to be

related to engineering per se but could be about the human body, photography, etc. I myself have

built drones, model planes and helicopters.

If you could drive any car, what car would you drive?

Porsche Boxster, my current car.

If you weren't an engineer, what would you be instead?

Something related to electronics or software.

DANIL:

What is your favorite vacation spot?

For relaxation, a beach in Mexico. I also enjoy traveling through Europe. We haven't done much

travel in the last three years. We're hoping to start traveling again. The next place I want to

go is the Caribbean.

What is your favorite thing to do in your downtime?

I like to read books or look for interesting information about what's going on in the world.

What is your favorite world structure?

When I saw the Eiffel Tower in person for the first time, I was surprised at how they could have built

that at the time. It's impressive. There weren't computers then, and each and every part of this tower,

millions of different parts and sizes, all come together with precision. It amazes me, and I have no

idea how they could have done that. It's still beautiful after 150 years.

DANIEL:

What's your favorite sports team?

My son's soccer team and the girls team I coach. Coaching has been an amazing experience. I was able to

share my knowledge and it's a window to teach the girls life lessons. I like to tell them stories about

my four sisters and mom and how they impact my life, in the same way soccer has shaped my life. It's amazing

how coaching lets me plant a seed in their lives.

If you were stranded on an island, what 3 things would you want with you?

Soccer ball, knife, and some sort of cooking book and action book.

What has been your favorite project in your career?

The Doha Airport. It was a one-of-a-kind project and a once-in-a-lifetime opportunity. It was one of my

first jobs and I learned a lot from working on it. It was a big development milestone in my career.

BERKELEY UNIFIED SCHOOL DISRTICT

PLM is proud to contribute to the education of upcoming generations in California, and the work they are doing for Berkeley USD West Campus has been one of their favorite projects. Over the last 10 years, PLM has engineered various parts of the Berkeley campus, and most recently they have made improvements to the auditorium, gymnasium, and outdoor walkways working with CAW Architects.

The auditorium got a complete makeover with new light boxes, projectors, sound system, and seating. We were responsible for mounting and ensuring that all the equipment was secured in place. The most noteworthy upgrade to the auditorium was a new elevator going from ground level onto the stage.

We provided the structural engineering to convert an existing gymnasium building into a cafeteria as well as updated some outdoor walkways with canopies to allow for more light and created a convenient and brighter area for the students. The features and changes that PLM helped make will foster a positive learning environment and allow all students to participate in activities throughout the entire campus.

SBE - LBE - MBE Certified

THE COLOSSEUM

Emperor Nero ordered construction of the largest amphitheater of all time, the Roman Colosseum. Sadly, the architect of this infamous building is unknown. The design of the Colosseum proves the need for extensive plans, drawings and expertise, but we don’t know who to credit for the work.

More than 80 arches made of concrete surround the Colosseum and they are the main supporting point of the edifice. These arches carry the force of the weight down to the ground and out, creating compressive stress in the arch. Vaulted arches, specifically barrel vaults and groin vaults, were used to add strength without much weight. They provided more support because the thrusts dispersed weight to the supporting columns instead of the outside walls.

The Colosseum featured ‘state-of-the-art’ public convenience, which was unusual at this period in history. It had hundreds of water fountains, a sewer and drainage system, and public toilets. The issue of crowd control inside the Colosseum was also expertly addressed. There were 80 entrances, 76 of which were numbered. The numbered entrances were for the common citizens to use and the other 4 were for the Emperor and other people of importance only. The building was planned so that it could be evacuated in a couple of minutes.

The Fall of the Colosseum occurred when people began to question the cruelty that took place there. Slowly, due to negligence and some large earthquakes, it began to deteriorate and was unusable until the 1990s when restoration began. It is now the most visited monument in Italy and a main tourist attraction in the world. It has influenced many modern architectural masterpieces and inspired engineers and architects around the globe.

SBE - LBE - MBE Certified

THE METAVERSE AND OUR INDUSTRY

Six months ago, Facebook announced it would rebrand to "Meta" and would focus its future on the upcoming "metaverse". Since this announcement, the term "metaverse" has floated around the internet without much clear understanding of how it will affect our future. While the metaverse is typically associated with video games, it has the potentiall to be so much more. Daniel Silva, one of our talented structural engineers, has researched and pondered what changes the metaverse will bring to our industry.

Technical professionals can benefit greatly from seeing digital representations of their work manipulated and updated in real time. As this technology advances, we will be able to create a world that is parallel to our real world. This will help architects and engineers find weak links in their buildings and correct them before they are manually constructed. We will be able to identify problems virtually, and avoid them in reality.

Our transition from traditional office-based work to virtual work will be greatly enhanced with VR and AR interfaces. Being able to display models remotely will eliminate the need to travel and will be much more powerful than communicating over a Zoom call. Clients will be able to see various finishing options for their buildings and how they coordinate and look in real time, thus reducing the possibility of costly rework, delays, and change orders.

All of us at PLM are anxious and excited to see what the future brings with the full capabilities of the metaverse at our fingertips. What an incredible time to be working in this industry!

SBE - LBE - MBE Certified

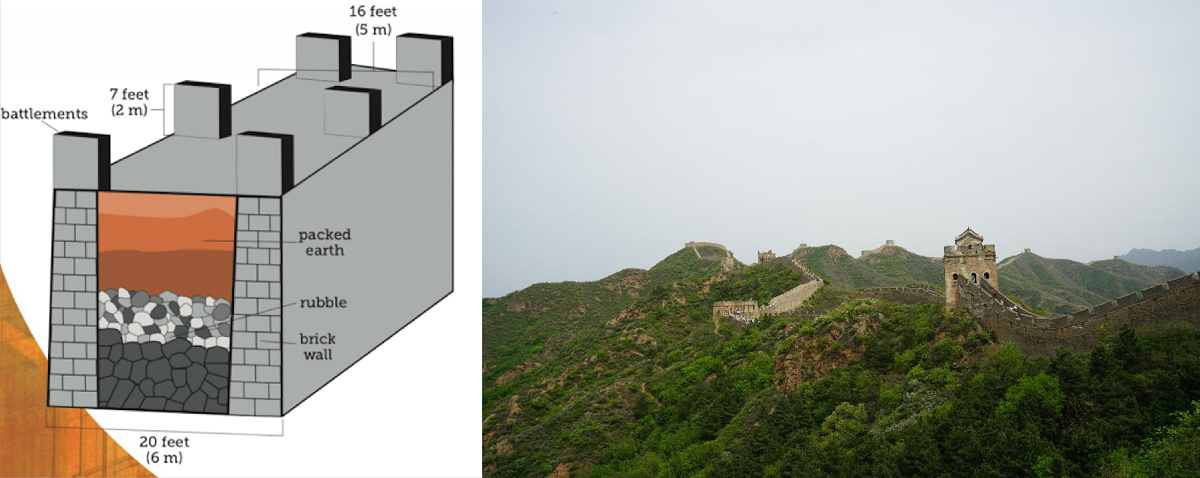

THE GREAT WALL OF CHINA

As we explore structural feats of the world, this month we look at the Great Wall of China. The Great Wall of China is, by many measures, the greatest structure ever built. Unsurprisingly, hundreds of thousands of laborers, prisoners, slaves, and soldiers built the wall starting in the 8th century BC until 221 BC, with revisions being made as recently as 1644 CE.

The Great Wall is an astonishing 13,170 miles long (21,296km), and weighs an estimated 58 million tons. There are an extraordinary 25,000 watchtowers along the wall, which were utilized primarily during the Ming Dynasty to help defend against Mongol attacks.

Because of the vastness of the tower and range of time and labor types, the wall has never been uniform. Builders of the wall used local resources. In fact, in parts of China where the wall crossed plains, the wall was simply built of rammed earth as opposed to brick and stone. When the wall was updated during the Ming Dynasty, brick and cement factories were made nearby so the wall had sufficient supplies.

The actual construction of the wall most commonly constitutes a 20 ft wide base with two outer brick walls. Inside is a rubble interior with packed earth covering the rubble. The top of the wall is 16 feet wide with 7 feet battlements erected along both sides of the wall.

The Great Wall of China has been a spectacle for millennia now, and somehow the more we learn about it, the more impressive it becomes.

SBE - LBE - MBE Certified

FLOATING FIRE STATION

On March 10, 2022, The San Francisco Fire Department unveiled the world’s second ever floating fire station. Our PLM team was crucial to the development of this unique building, having designed the superstructure of the fire station. There were several challenges to overcome in designing a floating structure, but our talented structural engineer, Daniel Silva, exceeded expectations and created a marvelous design with the help of the entire PLM team.

The original fire station on the Bay, at Pier 22 1/2, is a small wood structure that has been around since 1915. It no longer had the capacity to provide for the City’s needs, and since there’s not a lot of room for expansion onto the Bay, the only place to go was to the ocean. So that’s exactly what they did!

While in the design process, Daniel had to consider many factors that would not normally be an issue for a building on dry land. The floating motion, marine code, changing water temperature, and wind, are just a few of the elements that had to be considered in the process. The combination of all these loads was quite tricky, but luckily PLMs engineers are experts at thinking outside of the box and adapting to extraordinary circumstances.

Daniel Silva and Hardip Pannu attended the fire station ribbon cutting ceremony last month and were given a tour of the completed structure. Daniel said that it feels like you’re on a boat and even the light fixtures swing (like they are supposed to)!

"The new Fireboat Station 35 will improve the Fire Department’s ability to meet our emergency response needs today and into the future," said San Francisco City’s Mayor, London N. Breed.

SBE - LBE - MBE Certified

THOUGHTS OF UKRAINE

Our thoughts and prayers have been with our Ukrainian brothers and sisters over the last several weeks. The devastating Russian invasion has provoked deep emotions all over the globe, bringing people together to help, support, and fight for peace. Our own Danil Botoshanksy is a Ukrainian native. Although he left Ukraine in 1989, he cares deeply for his homeland and his patriotism remains.

Having close ties to Ukraine gives Danil a unique perspective amidst this global crisis, and he sends words of caution about believing everything we see in the media. "There are some differences between what is happening in Ukraine and what information we are hearing here [in the United States]. Some of this information needs to be filtered. Which army is doing better? Which army is progressing? It's difficult to understand these things at this point in time and get real information." Danil's communication with his Ukrainian contacts keeps him up to date on the current Ukrainian happenings, but even they cannot predict what tomorrow will bring.

Danil reflected on a time when he said "Ukraine and Russia before didn't have a border - people would just pass through and Russians lived in Ukraine and Ukrainians lived in Russia. People weren't tied to the region where they were born." Danil has fond memories of this beautiful, fertile land, with open borders and friendly relationships.

As we see the destruction of people's lives as well as the beautiful structures and architecture that surrounded them, we keep our Ukrainian friends both here and abroad in our thoughts.

SBE - LBE - MBE Certified

WE'RE LEAVING PAPER BEHIND–A TECHNOLOGY FOCUSED WORLD

PLM recently moved office spaces (you’ll find their new address below), and as with any move, they sifted through the assortment of documents that have accumulated over the last 10 of years. Albeit a tedious task, it also made the staff a bit nostalgic looking back through previous projects and reflecting on all the time, work, and endless amounts of paper that were used! Daniel Silva, one of PLMs finest structural engineers, couldn’t help but notice how so much of the work they previously did by hand is now done on the computer, and their paper footprint has significantly decreased in recent years.

In addition to minimizing desk clutter, converting paper-based content to a digital format opens up a world of possibilities for engineers. Daniel Silva is part of a "transitional generation", since he learned structural calculations by hand, but has now begun using powerful engineering software. "I'm fortunate to experience both sides. Less hand work and more software, but, you have to have experience to know what you’re doing. Learning it all by hand has given me the confidence to work with the software. You can still make mistakes with the computer too." Although software and a shift to the digital era allows us more flexibility in where and how we work, it does not replace the need for knowledge and experience.

This shift to digital work has been accelerated by the pandemic, which has forced many to adapt to remote work. Zoom and other video conferencing services have taken off, which will inevitably lead to VR solutions of the like. Virtual reality will allow for site visits and better and more personal connections — much like face-to-face interactions provide. Ironically, good things for the workplace have come from the pandemic, and we are approaching a very exciting digital future.

SBE - LBE - MBE Certified

OUTHE GREAT PYRAMID OF GIZA

To continue our travels around the world, today we will look at another amazing structure, The Great Pyramid of Giza. This pyramid is the oldest and last remaining of the original seven wonders. It was completed in 2560 BC and took about 20 years to build. To accomplish the task in this short amount of time, it is estimated they installed up to 180 blocks each hour. The diagonal sides of the pyramid are 550 feet- nearly as high as the Washington Monument!

Due to the ancientness of the structure, Egyptologists are left to infer much about the building process. The most widely believed theory is that the Egyptian people all helped construct the buildings as an act of civil service and were paid for their work. It was considered an honor to work on the pyramids.

The Great Pyramid was made out of limestone blocks that each weighed 1-2 tons. It is only speculated how they were able to lift the stones and form the structure. Many believe that the Egyptians pulled the stones on sleighs in the sand and then used a ramp and pulley system to lift them into place. With the limited resources and technology of the time, they constructed a structure weighing almost 6 million tons that is still intact today. May we all be inspired to be groundbreaking engineers like the Egyptians!

SBE - LBE - MBE Certified

OUR FIGHT AGAINST COVID-19 WITH TWIST BIOSCIENCE

For almost the last two years, our world has been turned upside down during the COVID-19 pandemic. Interactions with family, friends, and coworkers have been limited, businesses have shut down temporarily and permanently, and medical professionals have worked tirelessly to care for and bring relief to those affected by the virus. Despite the many obstacles we have faced, we have all adjusted and strived to play a part in ending this pandemic.

Once again, PLM has had the pleasure to work directly with a lab who is developing groundbreaking advances in coronavirus detection and gene therapies. Over the past few years PLM has worked with Twist Bioscience and DGA to design buildings, add chemical bunkers, anchor equipment, and modify any other part of their labs that they need as their research and work evolves. Twist Bioscience has been excellent to work with and we look forward to continuing our partnership and working toward relief from COVID-19.

SBE - LBE - MBE Certified

GENIUS OF SPIDER WEB ENGINEERING

In honor of Halloween, which is quickly approaching, we are exploring the incredible phenomenon of spider webs. This may seem like an unusual topic for a structural engineering firm to write to you about, but believe it or not, we have more in common with spiders than you might think!

Spider webs defy intuition and logic in many ways and will change how we design the world in the future. It is well known that spider webs are made of silk, which is five times stronger than steel of the same weight. It is not common knowledge, however, that spiders can also create a hybrid material that allows the web to stay taut, even when the web is pulled and released. This discovery inspired researchers at the University of Oxford and the Université Pierre et Marie Curie to create composite fibers that do the same.

Spider's web structure is also incredibly unique. As the web is spun, the thread stiffens, then stretches and then sharply stiffens again to transfer the pressure to the web as a whole. After even more pressure is applied, however, crystalline structures absorb the maximum strain until they break, creating localized damage but leaving the rest of the web intact. It has been discovered recently that when a small portion of the web has broken, the web in no way suffers. The spider can easily repair small local damage and often the web continues to operate without repair. This discovery could change how we view the engineered world around us, including that of buildings, cars, and infrastructure. Someday we will surely see more resilient and dynamic structures that will change the world for the better.

SBE - LBE - MBE Certified

RESIDENCE OF BUKOVINIAN AND DALMATIAN METROPOLITANS

Danil Botoshanksy, one of our senior structural engineers, came to San Francisco 33 years ago from the Ukrainian city Chernivtsi. This month, we would like to highlight another structural wonder, this time from Danil's home.

The Residence of Bukovinian and Dalmatian Metropolitans consists of a seminary, monastery, church, garden and park. It began in 1864 when architect Josef Hlavka won the tender for construction at just 29 years old. The work continued for 18 long years since construction was halted during the wet winter months. Bricklayers worked slowly and averaged just 100 bricks a day to ensure only the highest quality bricks were being laid. They measured the linear dimensions of each brick, and then they weighed and tapped for the detection of internal defects.

Before World War II, the buildings continued to function throughout all the changes happening in the region at that time. During the Second World War, the buildings were looted and damaged by fire. In 1955, the buildings began to be restored and they were given to the town's university and are now a main house for Chernivtsi National University. In June 2011, it was declared a UNESCO World Heritage Site.

It is said that Josef Hlavka worked tirelessly for 12 years on the Residence, resting only 4 hours a day, until he developed an illness that left him in a wheelchair. Here at PLM, we take better care of our personal health than Josef, but we also can promise a dedicated effort to all of our projects. We pride ourselves in being attentive, committed, and detail-orientated in all that we do, and who knows, maybe one day one of our buildings will be a UNESCO World Heritage Site too!

SBE - LBE - MBE Certified

WORKING FROM HOME

The last year has been unexpected and unique! We have all had to make adjustments and learn how to navigate a worldwide pandemic. It was difficult but also a learning experience.

One positive change that many benefited from was the opportunity to work from home. Before Spring 2020, many employers would not have considered allowing their employees to work from home full-time, but COVID-19 made it a necessity. And, in spite of the skeptics, working from home has been overwhelmingly successful among the majority of businesses. It is estimated that 33% of the workforce is currently remote and that more than 50% of those companies are open to a future hybrid schedule.

Our PLM team has been working remotely for more than a year now, and it has been a positive experience for everyone. Although there was an adjustment period at the beginning for Daniel, while his kids began remote learning and they were establishing a routine, he has come to love the flexibility. "What I like about working working from home is that I can set up my own schedule. Working late or early in the morning is something I enjoy because everybody is asleep so I have some silence." Danil also enjoys the flexibility and is grateful to save time by eliminating the hour commute each way to and from the office. Our team has learned a few tricks for working efficiently from home we'd like to share with you:

- Take breaks

- Have a designated workspace

- Communicate expectations with family or roommates

- Set work hours

- Get ready for your workday (get dressed and create morning routine)

SBE - LBE - MBE Certified

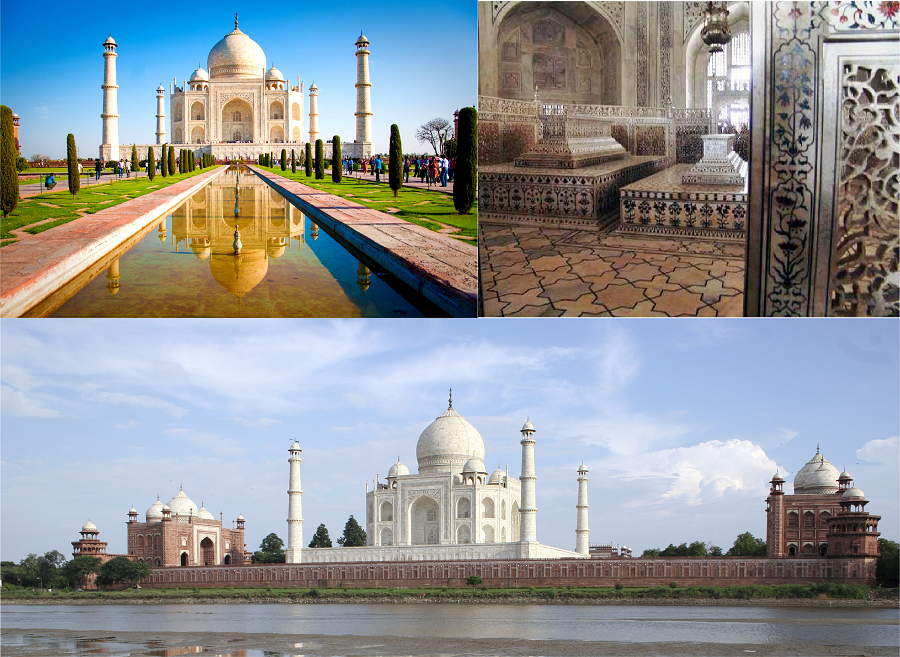

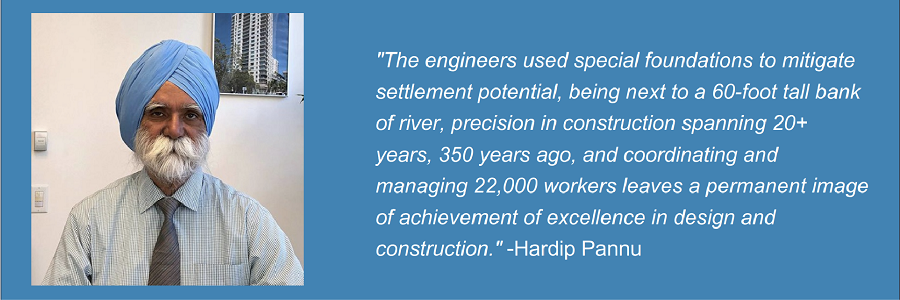

THE TAJ MAHAL

President of PLM, Hardip Pannu, is a native of India, which is home to the breathtaking Taj Mahal. Hardip has visited the Taj Mahal a couple times, and being an engineer, it is one of the most inspirational places to visit.

The Taj Mahal, one of the ‘new’ seven wonders of the world, was built by emperor Shah Jahan to immortalize his wife Mumtaz Mahal. The white color of the edifice symbolizes her purity, spirituality, and faith. Mumtaz Mahal lies in a secret marble chamber below the ground in the center of the dome.

The central marble dome is the focal point of this beautiful monument. Not only is it structurally magnificent, being self- supporting, but it is also symbolic and believed to be the link between heaven and earth. It seems as though when designing the Taj Mahal, no detail was spared to making it a true wonder. The four towers surrounding the Taj Mahal lean slightly outwards, and as a result they appear to be perfectly upright. If these towers were to fall in an earthquake, they would fall away from the central building, saving it.

When a person stands at the main gate and moves closer, the Taj Mahal seems to get smaller, and it grows bigger as the visitor walks away. It is said that as you leave, you take the Taj Mahal with you in your heart.

SBE - LBE - MBE Certified

PLM TRAINS NEXT GENERATION OF STRUCTURAL ENGINEERS

For nearly 11 years, Senior Structural Engineer, Daniel Silva, has been an invaluable member of the PLM team. Daniel's life motto is "do more", and this hardworking mentality has driven his ambition and accomplishments since he came to the U.S. as a Peruvian immigrant.

Last month, Daniel was invited to speak to a Structural Design class at SFSU for the second time. He shared his expertise and many of his projects to inspire the students to live by this personal mantra, "do more. Daniel's work on the Hamad International Airport, a floating fire station in San Francisco, and a rollercoaster motivated the students to learn more, work harder, and set goals for their future careers. The students were inspired and took advantage of the opportunity to ask Daniel to share deeper knowledge and insight about his work experiences. The presentation resonated with them, and Daniel was asked to be the SFSU School of Engineering Spring Graduation guest speaker.

While in Peru, Daniel received a bachelor's degree in civil engineering and a post bachelor's degree in urban planning. After moving to the U.S., he learned English and completed a masters degree in structural engineering and an MBA from SFSU. His "do more" mindset has helped him to overcome challenges and seek out amazing opportunities, despite being an immigrant and the initial language barrier. Daniel brings this same drive to every PLM project, and is a priceless asset to our team and clients.

SBE - LBE - MBE Certified

SCVMC COVID LAB

During the COVID-19 pandemic, Santa Clara Valley Hospital has been a safe haven for those affected by the virus to heal and keep their loved ones safe. PLM has had the opportunity and pleasure, as a company, to contribute to the COVID-19 relief effort through their work CUSCHIERI HORTON ARCHITECTS at the Hospital.

PLM has completed many projects at the Hospital over the years, with several more projects still on-going. Recently, they worked on the COVID-19 testing laboratory within the hospital. The Office of Statewide Health and Planning (OSHPD) requires all hospital equipment to be anchored in case of a seismic event to ensure the equipment is stable and functional. While the machinery was not designed to be fastened down, PLM created attachment methods for each type of equipment. This was particularly challenging for low-profile equipment, but PLM was able to make the attachments, regardless of the small space. Their unique solution uses special rails to hold the equipment legs to prevent movement. These rails are also quickly and easily detached for maintenance and cleaning.

On the surface, this project might not seem to be of much importance in the fight against COVID-19, but PLM has the unique position of making a difference in standard business practice. The OSHPD requirements are in place to create a safe environment. PLM was able to complete these specifications in a short period of time, just a manner of weeks, which allowed the laboratory workers to continue to perform their coronavirus testing. Having a safe and secure laboratory is essential for effective work. PLM is grateful for this opportunity and proud of their contribution!

SBE - LBE - MBE Certified

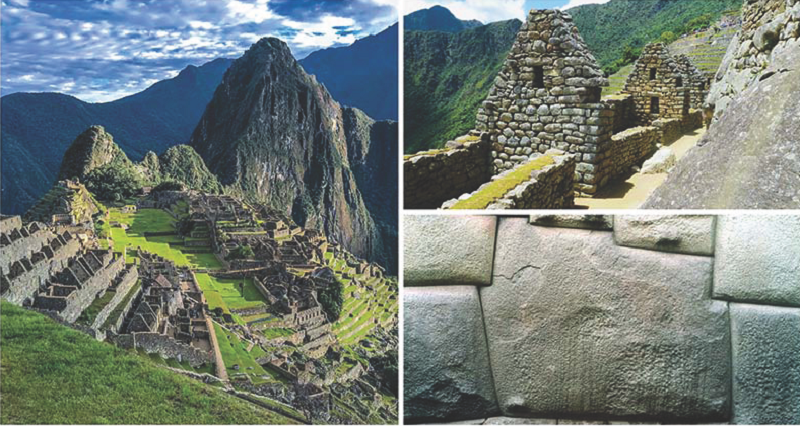

MACHU PICCHU

Here at PLM, we are fortunate to have many team members that bring diversity and global expertise to our office. Througout this year, we will highlight famous structures around the world, starting w ith monuments from a few team members' native countries.

Daniel Silva, one of our Senior Structural Engineers, is from Peru, home of the Incan citadel, Machu Picchu. Daniel has visited the site twice, once in high school and again on his honeymoon, both times renewing his connection to his native culture.

Machu Picchu is made up of roughly 200 buildings. Each structure is made of granite stone. You might be picturing regular, rectangular stone blocks, but the amazing and beautiful part of Incan architecture is their use of polygonal stones. Stonemasons hammered rocks against the granite to flatten the sides and create smooth edges that fit perfectly with the adjacent stone. No cement was used to hold them together - they fit like puzzles pieces, shaped to perfection in order to stand together.

The engineering of Machu Picchu was carefully and brilliantly planned. Another example of their ingenuity is in the "Stairway of Fountains" that supplied fresh, clean water to the city inhabitants. Using a canal system, the water flows from a pair of springs about 2500 feet away to 16 fountains in the city. The first fountain was next to the emperor's residence, giving him first access to the water. This water system is still in place and functioning today, centuries after its construction.

Machu Picchu is a UNESCO World Heritage site and one of the New 7 Wonders of the world.

SBE - LBE - MBE Certified

SEASON'S GREETINGS

AIRPORT DESIGN AND THE TRAVELER EXPERIENCE

Top: San Francisco International Airport Terminal 3E. Bottom left: San Francisco International Airport Boarding Area E, Right: rendering of new Doha, Qatar International Airport.

When designing an airport, it is key to create a positive, state of the art, progressive first impression that reflects favorably on both, the city and country in which it is located.

Although airports are designed with the purpose of efficiently moving people from one place to another, designers are redefining the traveler experience in exciting, striking ways. "Generally speaking, any airport has the same functions and needs," explains Hardip Pannu, Principal. "The structure is designed to accommodate and move large numbers of visitors. Check in, security, baggage handling, jet bridges, baggage claim in a most pleasant and exciting manner. All of these factors need to be accommodated."

This means the structural design must accommodate heavier than usual floor loads to accommodate more column-free space and floor-to-floor height. The Terminals and boarding areas at the San Francisco International Airport features natural light and visibility. "Clear lines of sight inside the building created design challenges PLM loves to tackle," says Hardip. "We applied creative technical and cost-effective solutions to design and construction challenges that will serve to shape the passenger journey."

PLM stays involved from design through the end of construction completion. We believe a positive and responsive team who is sensitive to budget, schedules and quality of design and documentation differentiates the firm from our competitors.

SBE - LBE - MBE Certified

SUCCESFUL RESIDENTIAL PROJECTS: LAYOUT, VALUE, AND QUALITY

At PLM, there are three critical considerations when designing residential projects:

- Understanding that the structural design must enhance the architectural vision and provide a flexible floor plan that can meet changing needs and patterns.

- Successfully minimizing the material cost of structures. "While designing the structural systems for the Landmaker high-rise residential buildings in San Jose," Principal Hardip Pannu describes, "we collaborated with Swenson Builders to design an optimal floor plan layout that was not only unique but ultimately yielded savings in construction costs. Barry Swenson's team and I were awarded a patent for this design."

- Creating a high-quality and flexible design. From a structural standpoint, this means the occupant never gives the design a second thought.

Pannu emphasizes, "You want to allow maximum flexibility not only for the designers but also for those who will be living in the spaces. The building is designed to remain in use longer and remain relevant to changing needs and patterns." We consider each structure we design to be unique. While basic design requirements remain the same, each building has its own story and design process.

Whether it’s exploring alternative structural layout options, applying creative solutions, or generating accurate construction documents, PLM always delivers value in their residential work.

SBE - LBE - MBE Certified

SAN JOSE'S AMERICA CENTER

The multi-phase America Center is made up of Class A office buildings and a parking structure built on a closed landfill next to the San Francisco Bay National Wildlife Refuge.

Overcoming Cross Contamination and Settlement

While the prospect of large tracts of developable land in urban areas is incredibly compelling,

building on a landfill presents several engineering challenges including foundation design to avoid

cross contamination during piling and settlement issues. "Designing structures to be built on top of 65

feet of trash that sits above mud required a creative approach," explains Daniel Silva, PLM Project

Engineer. "We designed with settlement in mind, using cantilever supports where concrete reinforced

pilings are drilled down to avoid excessive settlement."

Adaptive to Changing Code

Each phase consists of two, six-story office buildings. To ensure the buildings can adapt to new code,

PLM engineers designed a special lateral system. "While the buildings are structurally identical, we

incorporated both moment frame and eccentric brace frame design into the building’s lateral resisting

system to give us greater flexibility to adapt to code updates."

Connecting the Buildings

When an Amenity building was added to the scope of work, and PLM engineers were tasked with connecting its

lateral system to that of the garage – taking into account the floor elevations were not matching at all

levels. The innovative design solution connected the two buildings at the matching elevations to transfer

forces to the garage’s lateral system.

Award-Winning Green Design

Phase I of America Center was completed in 2009 and was pre-certified LEED Gold. In 2008 it was named the

"Green Project of the Year" for the private sector by the Silicon Valley Business Journal. Phase II that

is just completed includes a second set of 215,000 square foot buildings, a four-story parking structure

and 22,000 square foot amenity building. The project achieved LEED Gold Certification by the US Green

Building Council and is one of the largest LEED Gold projects in the Bay Area.

PLM has shown that it can meet the challenge of engineering issues associated with reclaimed landfills to create highly valuable and environmentally-friendly buildings.

SBE - LBE - MBE Certified

FIRST FLOATING FIRE STATION IN U.S.

San Francisco Fire Department's Fireboat Station 35, located at Pier 221⁄2 on The Embarcadero, is a precedent-setting project. The 16,000 sf, two-story station will be located behind the existing historic landmark Fire Station 35 and will sit atop a steel float structure. The float will be anchored on all four corners by guide piles that will allow for up to six feet of rise and fall. Pedestrian and vehicular ramps will connect the structure with The Embarcadero.

When Shah Kawasaki Architects, specialists in public safety architecture, were commissioned to design the station, they turned to PLM to resolve the challenges inherent in the structural engineering. "As this is the first project of its kind in the U.S., its unique conditions have generated many opportunities for structural innovation," states Daniel Silva, PLM's Project Engineer.

The project team has held long study sessions to determine the most efficient and accurate ways to meet all the different standards required by the marine and construction codes. PLM created a structural model of the facility, identifying and analyzing loads based on multiple criteria: 100-year storms, daily waves, temperature, and fatigue. A quick turn-around is another constraint, with structural design completion required by the end of design development.

"Having the chance to design a floating building is unparalleled," exclaims Daniel, "providing a design that will be used for the benefit of our community is a big incentive for our work."

SBE - LBE - MBE Certified

MEET DANIEL SILVA

"The beauty of working with Daniel and PLM Structural Engineers is they first try to understand the architects intent. Rather than trying to dictate how the structure must work, Daniel has always been very collaborative and attempts to make our projects better through structural design."

"The beauty of working with Daniel and PLM Structural Engineers is they first try to understand the architects intent. Rather than trying to dictate how the structure must work, Daniel has always been very collaborative and attempts to make our projects better through structural design."

As a young boy in Lima, Peru, Daniel Silva had his first experience with building when his father acted as general contractor on the construction of their new home. The experience had a profound effect on him, awakening a passion that continues to this day.

Daniel earned both his bachelor's and post baccalaureate degrees in civil engineering at the National Engineering University in Peru in the early 2000s, a Master of Structural and Earthquake Engineering from SFSU in 2014 and an MBA in 2017.

Daniel firmly believes in sharing his knowledge with others. Teaching his fellow employees has helped him improve his existing knowledge and better explain concepts as both a mentor and an engineer. Your spreadsheets and drawings are a mirror of your own knowledge, he explains. When calculations are easily interpretable by others, it shows that the concepts are clear in your own mind.

Daniel takes pride in creating full responsibility for every project he handles. Every time I walk past a project I've worked on, I know a little bit of me is in there.

SBE - LBE - MBE Certified

MAIN + MARSHALL: WHEN COLLABORATION EQUALS SAVINGS

"The level of detail PLM provided in the structural plans to construct the concrete super structure to was unsurpassed. PLM provided a well-coordinated and complete set of detailed plans. At times of need when issues arose, PLM always made themselves available in support of the project, a true trade partner, and team player. I really enjoyed working with them on this project."

"The level of detail PLM provided in the structural plans to construct the concrete super structure to was unsurpassed. PLM provided a well-coordinated and complete set of detailed plans. At times of need when issues arose, PLM always made themselves available in support of the project, a true trade partner, and team player. I really enjoyed working with them on this project."

Main + Marshall is a leading example of a building that fits the needs of urban residents, while complementing Redwood City's vision for the downtown area in both design and scale.

Long before the building's completion in 2016, the PLM team recognized the challenge of engineering this high-density residential building comprising 196 apartments and an attractive list of luxuries. The 370,000 SF building maintains a three-story height limit along Main Street, with eight stories behind and two levels of subterranean parking.

Structural components, including a solid mat foundation, street and underground cast-in-place concrete floors, and post-tensioned floor slabs above, were another challenge. The floor plate steps back as it goes up, a pleasing architectural element.

"With the grid-to-grid dimension change from the parking to residential levels, the use of sloping columns, and the need to maximize space within a downtown location, we had to be on our toes as the lead structural engineers," said Daniel Silva, Associate and PLM's Project Manager.

PLM worked closely with Christiani Johnson Architects early on to select the optimized column grid minimizing the floor slab thickness, properly locate shear walls that will alleviate major torsion irregularities. The collaboration benefited the building immensely by reducing the overall building weight and reducing the seismic forces. "Our previous experience is our best contribution to the project," said Daniel, "Our knowledge of various systems helped us find a more efficient and cost-effective solution."

SBE - LBE - MBE Certified

OFFICE BUILDINGS

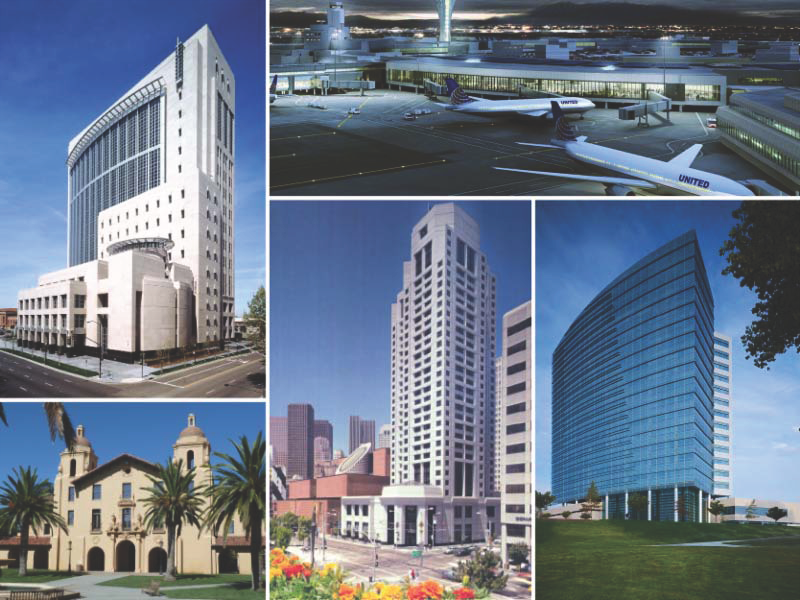

Clockwise from top left: CalSTRS Headquarters in Sacramento, America Center in San Jose, 535 Mission in San Francisco, Juniper Networks in Sunnyvale, Brocade (@First Campus) in San Jose.

For nearly 40 years, our Principals have been at the top of their game in office building structures. We've completed dozens of seismically sound projects in the Bay Area and throughout Northern California that demonstrate our commitment to strength, precision, and efficiency. From the Juniper Networks in Sunnyvale and America Center in San Jose to CalSTRS in Sacramento, we are more than capable of working on any office structure.

Whether retooling and retrofitting an older building for a tech company or completing the structural design for a high-rise that will take in the stunning San Francisco skyline, PLM engineers are thorough, adaptable, and collaborative.

We go above and beyond. We work closely with the architect early on, listening intently to their design needs and the overall vision for the project. We offer creative and efficient design solutions that optimize the structural layout and save the owner money on their project.

We're a true team player in every sense. Structurally challenging designs or a fast-paced construction schedule are opportunities for us to dig deep and find creative solutions.

From building and seismic codes to construction materials to structural analysis, PLM engineers provide the experience and expertise necessary for easy to build, cost-effective office structures.

SBE - LBE - MBE Certified

MEET DANIL BOTOSHANSKY

Have you ever visited the W Hotel in San Francisco?

If you've been to this 33-story luxury hotel in the heart of downtown, you've experienced Danil Botoshansky's work. And multi-story hospitality projects are just one of his many structural engineering feats.

Following in his Uncle's Footsteps

While still in middle school, Danil's uncle, a structural engineer, introduced him to the drafting board and taught him to draw and read drawings. Danil knew then that he wanted to follow in his uncle's footsteps. In 1972, he received the equivalent of a master's degree in Civil and Structural Engineering from Kishinev Polytechnic Institute in Moldavia, the former USSR.

Creating Long-term Relationships

After 16 years of working in Europe, Danil moved to the Bay Area, where he has been providing clients with solid structural solutions ever since. He prides himself on creating long-term relationships - both with clients and with team members. He enjoys mentoring junior engineers in the office and he leads by example in ensuring excellent communication on his projects.

A Diverse Project Portfolio

Danil has worked on many different project types. His portfolio includes multiple SFO Airport projects, the State Office Complex in Sacramento; 100 Grand residential tower and parking in Oakland; Highland Alameda County Hospital in Oakland; the Parkland Mystic Timbers rollercoaster at Kings Island Amusement Park in Mason, Ohio; and many other coasters all over the world.

Staircases on Pinterest and Other Interests

Danil can't help but incorporate structural design into his hobbies - he has collected over 800 staircases on Pinterest so that he can study them and understand how they work structurally. He also enjoys reading books, traveling, and spending time with his four grandchildren.

SBE - LBE - MBE Certified

SEASON'S GREETINGS

KEEP YOUR HAND AND FEET INSIDE

Top left: Harley Quinn Crazy Coaster at Six Flags Discovery Kingdom, Bottom left : Superman Ultimate Flight at Six Flags Discovery Kingdom, Top and bottom right : Troy at Toverland, the Netherlands.

You step into the seat of your favorite roller coaster, pull down your lap bar and the ride assistant comes by to make sure it is securely fastened. The

coaster slowly clicks its way up the track to its highest point and suddenly lurches forward, hanging momentarily in midair, then

begins its descent. Your stomach drops. As the ride reaches top speed of 150 mph,

your entire body presses back against the seat, your hair is flying, and your adrenaline is pumping as you join in

the ear-piercing screams of all the thrill seekers around you.

Chances are at this moment you aren't thinking about the structural engineering that ensures the ride is capable of taking the

loads of the cars and its passengers - time and time again - bringing them safely and securely back to the starting point.

You might not have thought about it, but the engineers at PLM have. Roller coaster and thrill ride engineering is a specialty.

Understanding how all the pieces fit together, calculating the loads, and applying inertia forces takes experience. PLM has that experience.

Harley Quinn Crazy Coaster and Superman Ultimate Flight at Six Flags Discovery Kingdom? The PLM team engineered those.

Troy at Toverland in the Netherlands? Yep. In fact, the PLM team is responsible for nearly fifty coasters and rides throughout

the United States and Europe.

Behind the firm's thrill rides are a team of professionals who have built a reputation for being innovative, effective and precise.

"It's an exciting project type," says Senior Associate Danil Botoshansky. "Over time, we created specialized software to help

us design. It took a long time to develop these special tools, but we did it so we can design the next one quickly and effectively."

SBE - LBE - MBE Certified

MEET HARDIP PANNU

An Early Start

Hardip Pannu knew at an early age he was bound for a career in engineering. His course was guided by an amalgamation of interests: a love of math, an understanding of all things technical, and an architect uncle. He completed his Bachelor's degree in Civil Engineering as the top Engineering student in the state of Punjab, India. He applied and was accepted to the University of Wisconsin at Madison, where he earned his Master's degree in Civil Engineering.

The Phoenix Years

Hardip's award-winning structural design career began in Phoenix, where he spent ten exciting years and received a technical excellence design award for One Columbus Plaza. Greater Phoenix is dotted with structures that he designed, including Sky Harbor Airport's Terminal 4.

On to San Francisco

When he joined Martin, Middlebrook & Associates in San Francisco, in 1989, Ron Middlebrook would introduce him as the firm's trouble-shooter; he created proprietary computer-based analysis methods that became standard practice. When the firm changed ownership and became Middlebrook + Louie (M+L), he was made a Principal. In 2010 the company dissolved, and he formed PLM with two of his M+L partners.

Solid Structures

Hardip has led the structural design of many major projects, such as the International Boarding Area "G" at SFO, the W Hotel in San Francisco, Highland Alameda County Hospital's Koret Emergency Outpatient Center in Oakland, and the CalSTRS Headquarters in West Sacramento.

Hardip's thorough understanding of engineering and intuitive thinking allows him to create simple and easy to build yet innovative solutions to complex structural problems.

Just for Fun

Outside the office, Hardip has a pilot's license and enjoys assembling electronic circuits, model airplanes, model helicopters and drones.

SBE - LBE - MBE Certified

DO YOU KNOW PLM?

With more than 43 years of experience in structural engineering, we're certain you're familiar with some of the office, mixed-use, recreation, and hospitality projects that have remained our specialty from day one. From San Francisco's Moscone Convention Center and W Hotel to the seismic rehabilitation of Stanford's Old Student Union to Sacramento's U.S. Courthouse and Federal Building, we've had a hand in crafting and re-crafting some iconic structures.

It all started back in 2010 when three Principals from the dissolved Middlebrook + Louie joined together to form PLM.

These Principals - Hardip Pannu, Jeppe Larsen, and Bob McCartney - were the structural engineers of choice for many of northern California's top architects, developers, and design/build contractors.

Eight years later, PLM remains a structural engineering firm that maintains a reputation for skill and precision on projects both large and small. We deliver personalized service on every undertaking, from concept through completion. Our dedicated and experienced staff is committed to using creative approaches to arrive at intelligent, innovative and cost-effective solutions.

SBE - LBE - MBE Certified

WAVE MACHINE

PLM provided the Structural Design of the Track Supports, Foundation and support structures for this amazing Wave Machine in Lemoore, California. In addition to the Structural Design of all types of buildings, the design of entertainment rides is another area of our structural design expertise.

SKY WARP

In addition to the Structural Design of all types of buildings, the design of structural components of the entertainment

rides is another area of our structural design expertise.

Ride Creators: Skyline Attractions

ARCHIVES

JOIN eNEWSFeb 2023

Oct 2022

Aug 2022

Jun 2022

May 2022

Apr 2022

Mar 2022

Feb 2022

Jan 2022

Nov 2021

Oct 2021

Aug 2021

Jul 2021

Jun 2021

May 2021

Apr 2021

Feb 2021

Dec 2019

Nov 2019

Aug 2019

Jul 2019

May 2019

Apr 2019

Mar 2019

Feb 2019

Jan 2019

Dec 2018

Nov 2018

Oct 2018

Sep 2018

Aug 2018

Jul 2018